MRS

Who we are

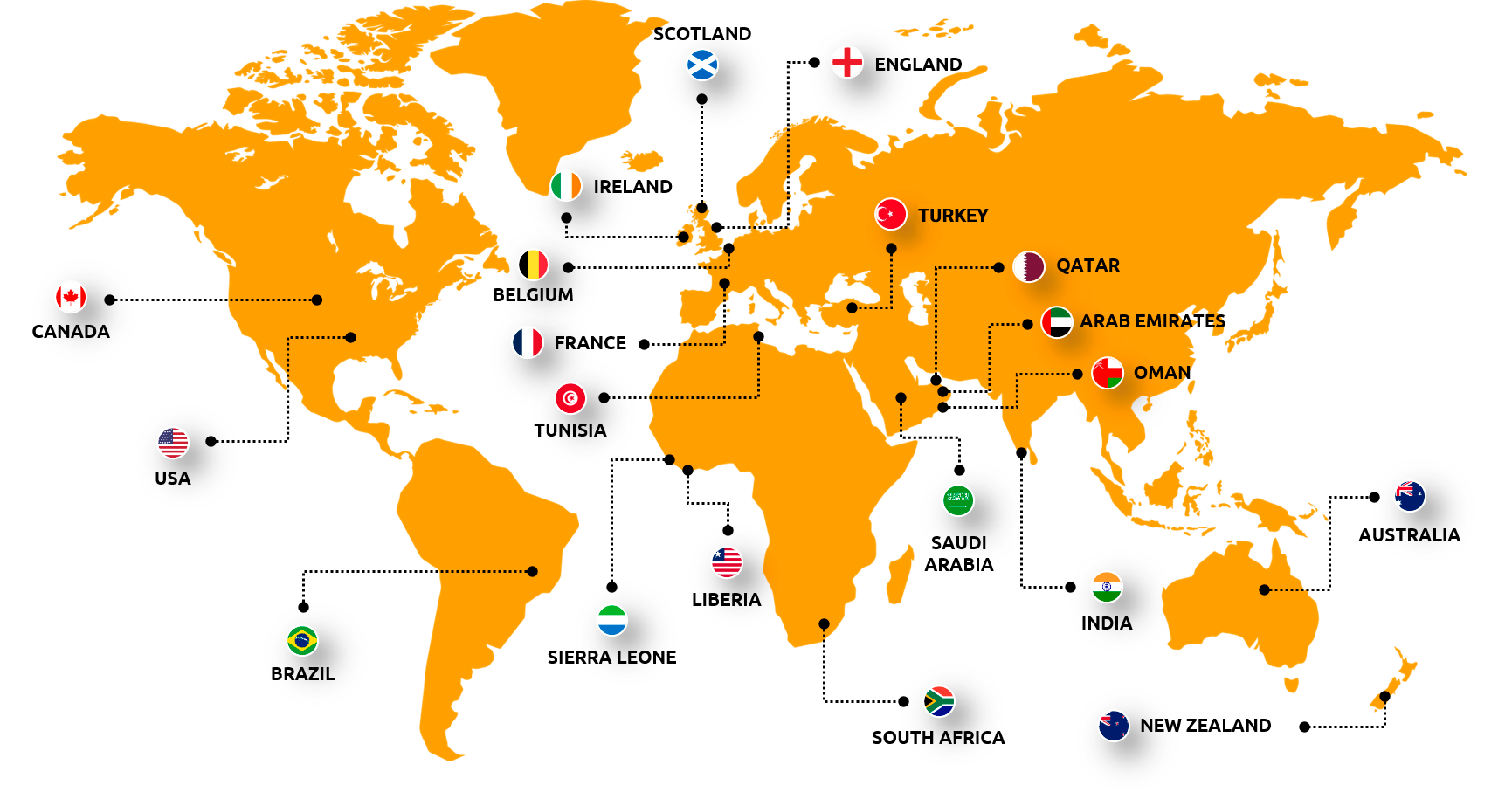

Moisture Reduction Systems is a 100% British company, based in London, providing solutions across the world for more than 20 years. We work to reduce the moisture content of granulated materials, resulting in gains in transportation, loading, handling, safety and other stages of the process as well as providing significant environmental benefits.

What we do

Moisture Reduction Systems Limited provides the service and the solution to the Mining Industry and associated material providers through our Accelerated Moisture Reduction or AMR System and draws upon 55 years of engineering and geo-technical experience from across the world.

Our patented system significantly reduces the drying time of granular material stockpiles. This leads to and continues to provide substantial cost savings for material providers. Whether the issue faced is one of moisture content of the material for shipping or loading, or handling on site, or to provide a more efficient and safer working environment, or simply to provide an effective water recirculation system, or to reduce escalating costs, we have the solution for you.

First 1 million tonnes per year under management by MRS

First system installed in Saharan Africa

System installed across The Middle East

MRS reaches 10 million tonnes per year processed

MRS expansion into sub-Saharan Africa enabling DSO to be loaded direct from mine to ship

Establish base in India

First system installed in India Coal for steel making reducing coal from 12% down to 6.2%

MRS expansion in USA silica sand market

First system on Iron Ore in India added

First Iron Ore system in Canada added and installed in Arctic region

First Discussions with Brazilian Mining companies

MRS establish Brazil office

Multi-site installation plan implemented in USA of 5 sites installed at same time

First Iron Ore system installed in Brazil

MRS 2.0 system technical research begins

MRS 2.0 installed across southern Brazil iron ore corridor

Reach 50 Million tonnes per year processing

MRS invited to install first system in Australia on most technologically advanced iron ore project of its kind in the world

Sustainability

Sustainability is an important and ever-growing requirement from our customers and material producers. At every stage, we are committed to reducing energy use and waste. The clean water that we remove from the material stockpiles is of such a high quality that it can be discharged back into the natural and local water sources, whether that be sea, lake, or river.

Furthermore, the global demand for recycling of energy and offtake uses from the primary process is only increasing and our system and technology allows the water that we remove to be recycled back into the production process, therefore reducing the water extraction from the natural environment.

We believe that our solution will provide a product that puts the control back in our customers’ hands.

Our numbers

COAL

SAND

IRON ORE

OUR SOLUTION

Our technology, with a registered global patent, can be used with the most diverse types of materials:

In addition to the benefits in transporting and handling materials, the moisture reduction provides environmental gains, increases the stability of the piles, enables water reuse and reduces energy consumption in the processes.

Technology

Our system uses no thermal energy. The operation utilises the creation and control of negative pressure and low-use electricity consumption. For example for a 100m x40m stockpile, the energy used is only two 10Hp motors.

Advantages

Quick drying

of

the material

Environmental

gains

Possibility of

re-using water

Reduction

of FMP levels

Increase in transport and handling capacity

Energy savings

across the processes

TML guaranteed and consequent reduction in transport risks

Elimination of double handling in the stockyard

MRS LAB

MRS is available to carry out free tests on materials in order to identify their behavior. Click below to request your test.

CASES WITH DIFFERENT MATERIALS

Iron Ore

MRS is the leading provider of mineral drying and handling services. We have operated on sites across the globe and in keeping with our forward-looking approach, we are enjoying the development of our expertise within the iron ore market.

Coal

At the generation of power process stage, the optimum target for producers is to obtain the maximum amount of energy that is released. One key element that adversely affects the handling of coal and impacts on the operation and efficiency…

Sand

The sand industry along with other material processors face mounting costs when their materials, if quarried wet, have to be stockpiled to allow gravity drainage to take place before they are eventually force dried in kilns, or oil-fired furnaces.

Bauxite

In line with our diversified project basis, we are acutely aware of the strict requirement for providers and suppliers to know the moisture levels of their product, particularly in transport and for the industrial force-drying of bauxite in kilns…

Tailings

One of the most important parts of the mining process and in the production and processing of raw ore, is what to do with the reject and waste material: the tailings. Particularly with the reduced solids content these tailings…

CLIENTS AND TESTIMONIALS

Testimonials

WHAT'S NEW!

Feel free to follow MRS on social media and keep up to date with our news!

CONTACT

Talk to MRS! We’re ready to receive your message and we’ll get back to you as soon as possible.

HEAD OFFICE

Mansfield House

1 Southampton Street

London

WC2R 0LR

T: +44 (0) 203 397 8565

M: +44 (0) 755 103 03 07

[email protected]

OFFICES

Australia

Unit 5, 254 Rokeby Rd

Subiaco WA 6008

Brazil

Av. Prudente de Morais, nº 135, 6º andar

Santo Antônio, Belo Horizonte, MG

South Africa

no. 5 San Marco Street

Seaward Estates – Ballito, 4020,

KwaZulu-Natal

TESTING LABORATORY

Unit B4 Cirrus Court

Commercial Road

Aviation Business Park

Christchurch

Dorset

BH23 6BW

[email protected]